Output requirements: Select models according to daily/annual ,

output (small household 0.5-1 tons/hour, medium 3-5 tons/hour, large 10 tons/hour or more).

Uses: household heating (small flat die), commercial heating (ring die), industrial power generation (large ring die or stamping type).

Specification: Common diameter 6-10mm.

Critical component quality:

Mold material: preferred alloy steel (such as 20CrMnTi), heat treatment hardness, life ≥500 hours.

Roller durability: Tungsten carbide coated roller can extend the service life by more than 30%.

Transmission system: Gear box needs IP54 protection grade, bearing brand recommended SKF or NSK.

Applicable material classification:

Typical ingredients:

wooden materials wood chips, sawdust, wood shavings, twigs, bark, wood processing waste.

Features: High lignin content (natural adhesive), easy to form, high particle calorific value (4200-4800 kcal/kg). Adaptation model: ring die particles machine (high pressure molding effect is good.

agricultural wastes

Straw: corn straw, wheat straw, rice straw.

Shelly: rice husk, peanut shell, coconut shell, palm shell. Other, bagasse, cotton stalk, haulm.

Others: bagasse, cotton stalk, bean straw.

Features: High fiber content, some raw materials need to be crushed to 3-5mm, may need to add adhesives (such as 1-3% starch or lignin).

Suitable model: high pressure ring die or stamping pellet machine (for high fiber raw materials).

Energy plant

Energy plant

Typical ingredients: switchgrass, Miscanthus, sweet sorghum, fast-growing forest (e.g. eucalyptus).

Features: Specially planted for energy production, need to control the harvest moisture (≤20%).

Other organic waste

(various types according to the actual material, Shinread engineers do selection)

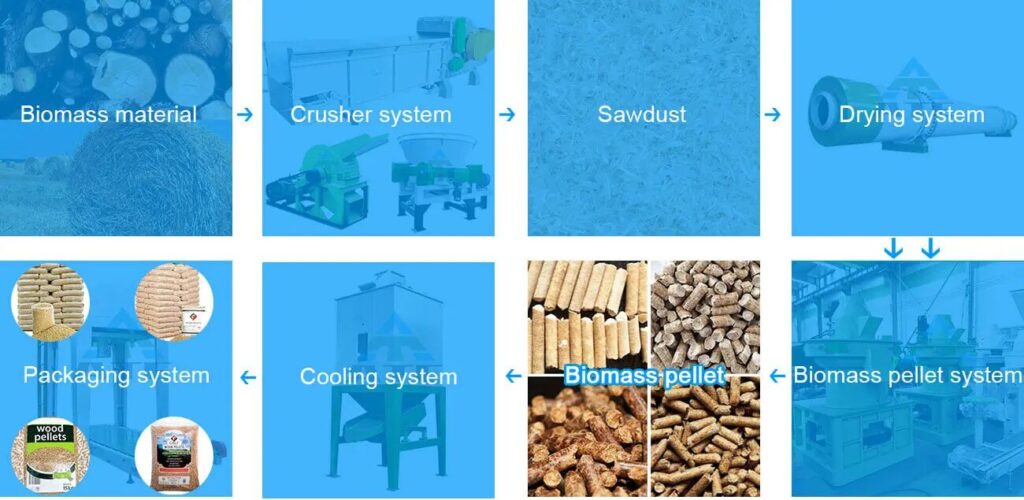

Preprocessing requirements crushing: particles machine feed size usually < 5 mm (straw classes need to use hammer type crusher).

Pretreatment :

Drying: Roller dryer or natural drying to the target water content.

Mixing: Mixing a variety of raw materials can improve the molding rate (such as wood chips + straw by 7:3 ratio).